Introduction to Scroll Compressors

Scroll compressors have become a vital component in various industries due to their efficiency and reliability. These compressors are used extensively in HVAC systems, refrigeration, and even in automotive applications. In this article, we will explore what a scroll compressor is, how it works, its benefits, and its applications across different sectors.

What is a Scroll Compressor?

Definition and Basic Functionality

A scroll compressor is a type of positive displacement compressor that compresses air or refrigerant by using two interleaved scrolls. One scroll remains stationary, while the other orbits around it, compressing the gas between the scrolls. This process is known for its smooth and continuous operation, which results in fewer vibrations and quieter performance compared to other types of compressors.

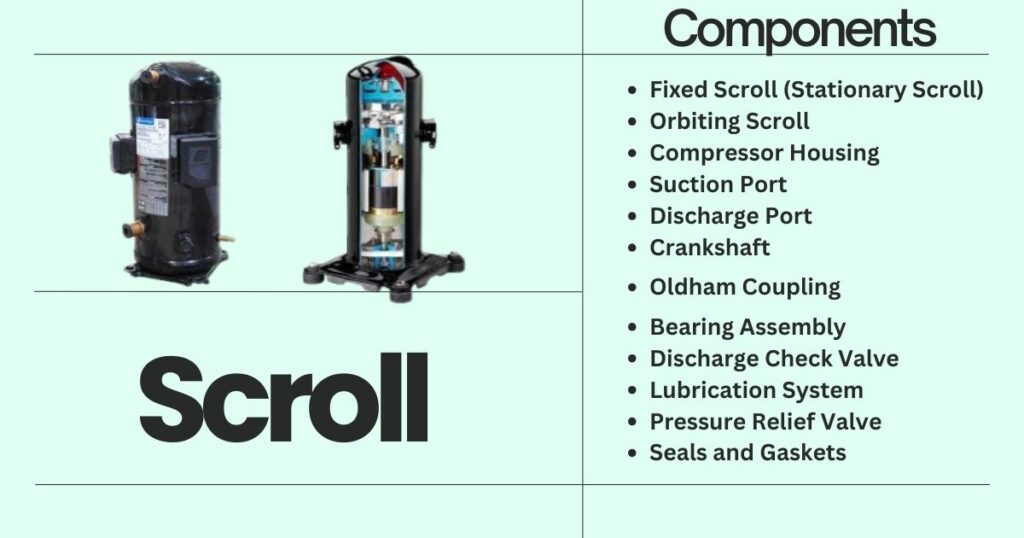

Key Components of a Scroll Compressor

- Fixed Scroll: The stationary part that serves as the compression chamber.

- Orbiting Scroll: The moving part that compresses the gas by orbiting the fixed scroll.

- Motor: Drives the orbiting scroll to create the compression effect.

- Suction and Discharge Ports: Allows the intake and release of the refrigerant or air.

How Does a Scroll Compressor Work?

The Compression Process of Scroll Compressor

- Intake: The refrigerant or air enters the compressor through the suction port.

- Compression: The orbiting scroll moves in a circular motion, compressing the gas between the scrolls. The gas is gradually compressed as it moves towards the center of the scroll.

- Discharge: The compressed gas is then released through the discharge port, ready for use in the system.

Advantages of the Scroll Compressor Mechanism

- Continuous Compression: Unlike other compressors that have pulsating flows, scroll compressors provide continuous, smooth compression.

- Lower Noise Levels: The scroll design reduces vibrations, leading to quieter operation.

- Increased Efficiency: The consistent compression process minimizes energy losses.

Benefits of Using a Scroll Compressor

Energy Efficiency

Scroll compressors are renowned for their high energy efficiency. They require less energy to operate compared to other compressor types, making them an eco-friendly option. This efficiency translates into lower operational costs, especially in large-scale HVAC systems.

Reliability and Durability

Due to their simple design with fewer moving parts, scroll compressors are more reliable and have a longer lifespan. The reduced wear and tear mean less frequent maintenance and downtime, which is crucial for industries that rely on continuous operation.

Quiet Operation

The smooth, continuous motion of the scrolls results in quieter operation. This makes scroll compressors ideal for applications where noise levels need to be minimized, such as in residential HVAC systems or medical equipment.

Compact Design

Scroll compressors are generally more compact than other compressor types. This compactness allows for easier installation in tight spaces, making them a popular choice for modern HVAC systems and refrigeration units.

Applications of Scroll Compressors

HVAC Systems

Scroll compressors are widely used in heating, ventilation, and air conditioning (HVAC) systems due to their efficiency and quiet operation. They are particularly popular in residential and commercial air conditioning units.

Refrigeration

In the refrigeration industry, scroll compressors are used in both commercial and industrial refrigeration systems. Their ability to maintain consistent temperatures and energy efficiency makes them ideal for refrigeration applications.

Automotive Industry

Scroll compressors are also used in automotive air conditioning systems. Their compact design and efficiency help improve fuel economy and reduce the overall weight of the vehicle.

Industrial Applications

Scroll compressors are utilized in various industrial processes where efficient and reliable air compression is required. Their ability to operate continuously with minimal maintenance makes them suitable for demanding industrial environments.

Comparison with Other Compressor Types

Scroll Compressor vs. Reciprocating Compressor

While reciprocating compressors are more common and cheaper, scroll compressors offer superior energy efficiency, quieter operation, and reduced maintenance needs. However, reciprocating compressors may still be preferred in certain heavy-duty industrial applications due to their robustness.

Scroll Compressor vs. Rotary Compressor

Scroll compressors generally offer higher efficiency and quieter operation compared to rotary compressors. However, rotary compressors may be chosen for applications where cost is a primary concern.

Maintenance Tips for Scroll Compressors

Regular Inspections

Conduct regular inspections to check for any signs of wear or damage. Ensure that the motor and scrolls are functioning correctly.

Lubrication

Ensure proper lubrication of the moving parts to reduce friction and wear. Use the recommended type of oil to maintain efficiency.

Cleaning

Keep the compressor clean and free from dust and debris. Regular cleaning helps in maintaining optimal performance and prolongs the lifespan of the compressor.

Monitoring Performance

Regularly monitor the performance of the scroll compressor. Any decrease in efficiency or unusual noise should be investigated promptly to prevent further damage.

Conclusion

Scroll compressors offer a combination of efficiency, reliability, and quiet operation, making them a preferred choice across various industries. Whether used in HVAC systems, refrigeration, or automotive applications, their advantages over other compressor types are clear. Understanding how scroll compressors work and their benefits can help in selecting the right compressor for your specific needs, ensuring long-term performance and energy savings.